How to: Portable Church Rolling Storage Carts (part 1)

When Clarity Church launched, we were very scarce on capital for some of the things that some church plants have. We were definitely scarce in capital compared to multi sites and extended campuses. Despite this reality we knew we needed to create a mobile church system that made it as easy as possible for volunteers to get involved.

We looked at Portable Church Industries, Church in a Box, and Church on Wheels for their mobile storage solutions, but it was just way too expensive. So what did we do? We scoped out a couple of churches who owned these "name brand" boxes, wrote down their specs and built them at half the cost ourselves. Because I know there are many church planters out there who may be in the same situation we were when we launched I want to share the knowledge as much as possible. More new churches means more new followers of Christ. So this is a post on how we build out enclosed storage carts. In another post I'll explain how we built our rolling carts for bins, and then in another I'll explain the cart we built for our lights, and then finally a cart for our pipe and drape.

So here's my best attempt to explain what we did:

DIMENSIONS

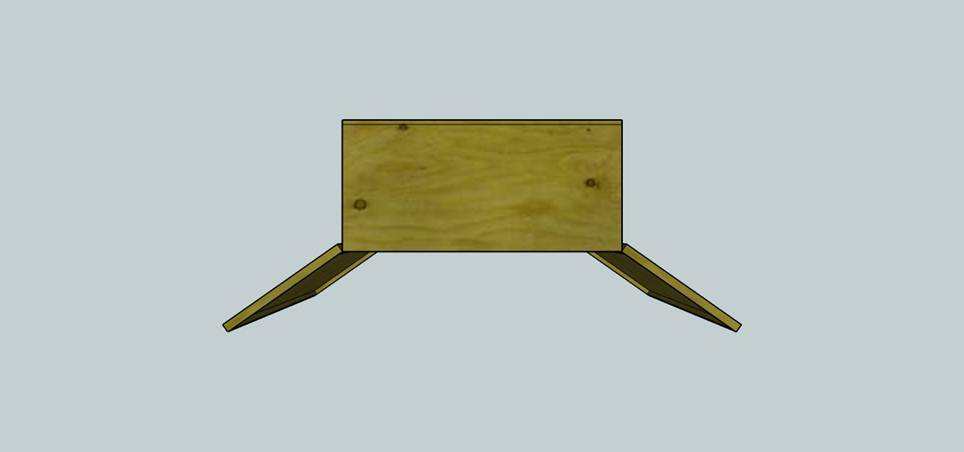

This is a 2' x 4'-1/2" cart. The height of your cart will be determined by your trailer's door height. We built our carts so that they are 5' 10-3/4' tall. (including casters)

MATERIALS AND TOOLS

Shopping List

(3) 4' x 8' x 3/4" Plywood or OSB (For back, sides, top and bottom)

(1) 4' x 8 x 7/16" Plywood or OSB (For front door)

(2) 6" Heavy Duty Rigid Casters

(2) 6" Heavy Duty Swivel Casters with lock

(2) 1-1/2' x 48" Continuous Hinges (also known as Piano Hinges)

(16) 5/16" x 2-1/2" Galvanized Hex Bolts

(16) 5/16" Galvanized Washers

(16) 5/16" Galvanized Nuts

(16) 5/16 Galvanized Lock Washers

Galvanized 10D nails

1-1/4" screws

Wood GlueOptional:

We used butterfly hinges that we order from Parts Express (https://www.parts-express.com/penn-elcom-l905-915z-butterfly-latch-zinc--262-200) as well as spring flex handles (https://www.parts-express.com/penn-elcom-h7154z-spring-flex-cabinet-handle-zinc--260-700) you can use other methods for keeping your doors closed and creating a way to "pull" on the carts.

We found these to be the best and are not too much more than traditional cabinet looks and pulls. Also, it has been the experience of other church planters that traditional locks that are meant for stationary cabinets do not hold up to the rigors of a mobile church

Cut list:

FYI...this is a cut list for a cart that is a total height of 5' 10-3/4"".

(1) 4' x 5'3" x 3/4" Plywood (for back)

(1) 4' x 5'3" x 7/16" Plywood

(2) 4' x 2' x 3/4" Plywood (for top and bottom)

(1) 5' 1-1/2" x 2' x 3/4" Plywood (for sides)

(1) 4'x 2' 1-1/8" Plywood (for rigid bottom)

Cut list instructions:

GENERAL INSTRUCTIONS

STEP ONE:

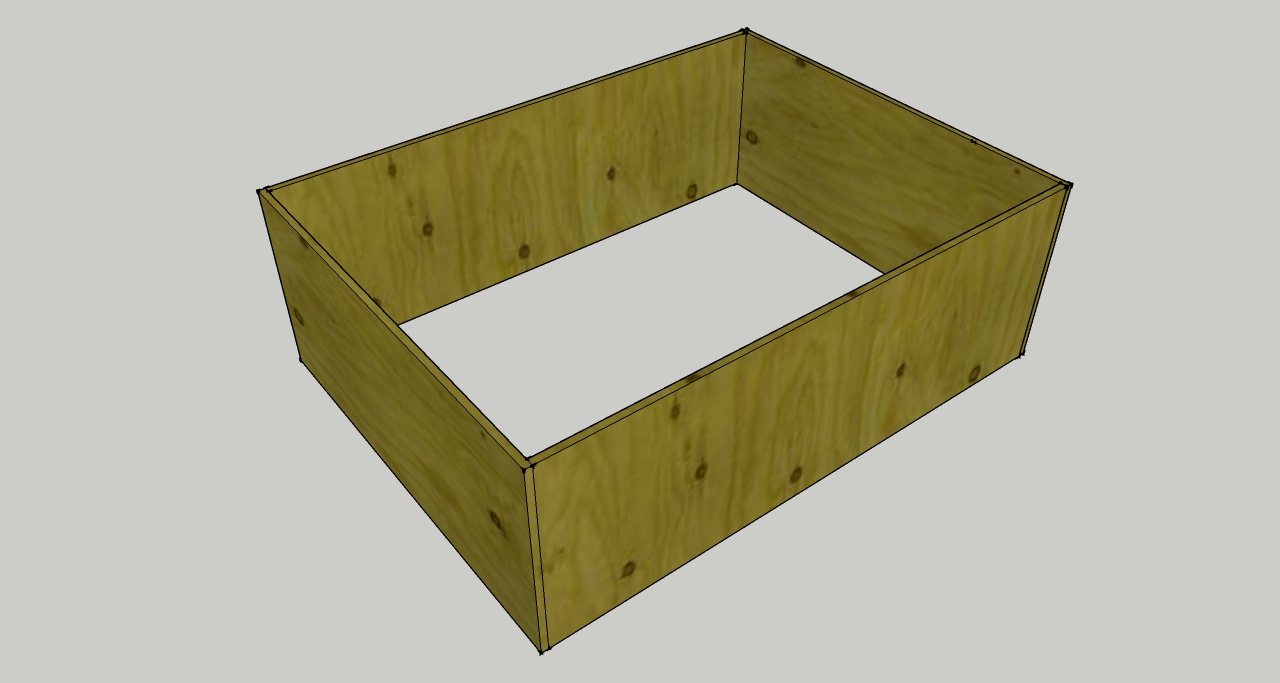

Start by building the top and sides with generous amounts of wood glue and galvanized 10D nails to build the box. Do not reinforce with screws yet.

STEP TWO:

Attaching the back: Place the 5'3" x 4' x 3/4" plywood on one side using generous amounts of glue and several galvanized 10D nails. If you cut your back ply square, not all your corners should be square. You can use a speed square or a framing square to check your corners.

Once you are confident your corners are square, then begin securing the back to the sides with a generous amount of 1-1/4" screws. Remember...this thing is going to get moved around a lot and hold your expensive equipment:)

Turn over and do the same thing with the 5'3" x 4' x 7/16" plywood